[QUOTE=burbank] If it's a Martin type, it's not too difficult to shorten it. Take the same required amount off the shaft and the u-channel. Just be sure the u-channel cut is dead square.

This worked fine for me using a Martin-supplied rod on a 12-fret, approx 23" scale neck for a size 5 guitar.[/QUOTE]

Tom, It's a Hot Rod Truss Rod from StewMac and I think having it stick out will not be problem, so perhaps no need to cut it and I'm also figuring this is a problem long ago solved by most on the board - not sure why I'm stuck.

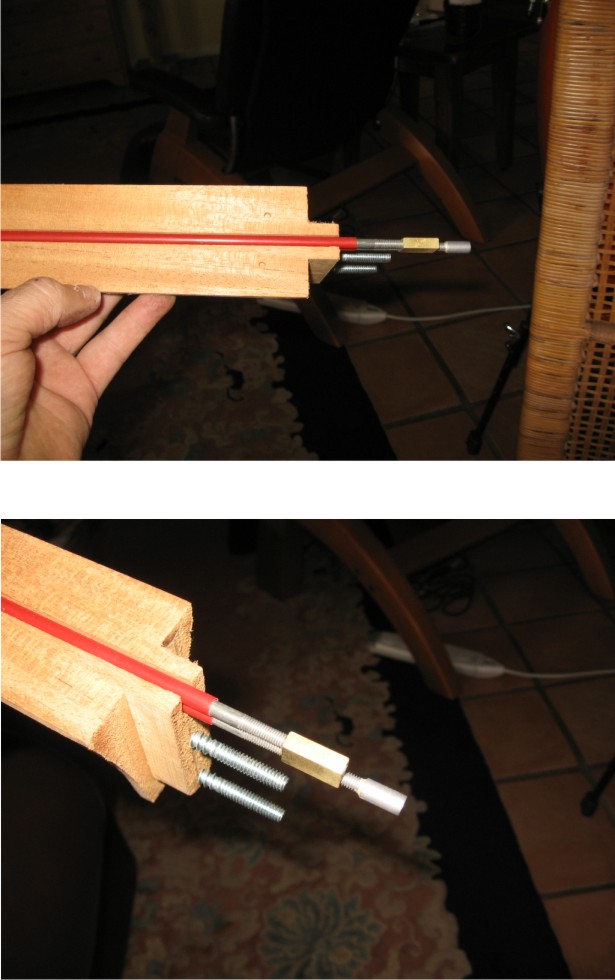

Here's a pic of what I'm thinking for the braces on the top and under the fretboard extension. May start a new thread with that pic and question as a bracing topic.